1. Disconnect the earth strap from the battery.

2. It will make for easier access if the bonnet is first removed, after marking the fitted position of the hinges to facilitate alignment when refitting.

3. On later models which have a plastic air intake assembly at the right-hand wing valance, withdraw the intake assembly into the engine compartment after pulling off the flexible pipe from beneath the wing.

4. Where fitted, detach the ignition shield from the front of the engine.

5. Disconnect the starter cable from the starter motor. Remove the starter motor (with distance piece, if fitted) from the converter housing.

6. On models with the starter solenoid mounted on the right-hand wing valance, disconnect the wiring and remove the solenoid.

7. Disconnect the engine tie-rod from the rear of the cylinder block.

8. Remove the oil filter bowl and filter head assembly from the transmission front cover.

9. Remove the nuts securing the radiator upper support bracket to the thermostat housing, and the bolts securing it to the radiator cowl, and remove the bracket.

10. Jack up the front of the car and support on stands located under the front sub-frame side-members.

11. Remove the air cleaner assembly and disconnect the exhaust down-pipe at the manifold flange. From underneath the car, also detach the exhaust pipe clip from the transmission casing.

12. Support the power unit with a hydraulic jack positioned under the transmission casing.

13. Remove the two bolts and nuts securing the righthand engine mounting to the sub-frame side member.

14. Now raise the right-hand end of the engine sufficiently with the jack to allow the converter cover retaining bolts and nuts and the clutch cover to be removed, but take great care not to let the cooling fan blades damage the radiator core.

15. Remove the cover retaining bolts and nuts, turn the converter cover slightly anti-clockwise and remove the cover complete with the engine mounting attached

. Note that the engine earth strap is normally secured by one of the cover front retaining bolts.

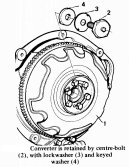

. Note that the engine earth strap is normally secured by one of the cover front retaining bolts. 16. Bend back the tab on the lock washer and unscrew the converter centre-bolt, while holding the converter from turning with a screwdriver inserted through the inspection hole in the converter housing.

17. Remove the centre-bolt and lock washer and lever out the keyed washer locating the converter to the crankshaft

.

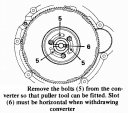

.18. Bend back the locking tabs and remove three equally spaced bolts from the centre of the converter

.

. 19. Rotate the converter until the slot in the end of the crankshaft is positioned horizontally.

20. Insert the plug of the special puller tool into the end of the crankshaft to protect the threads. Fit the puller tool onto the converter and screw in the centre-bolt until the converter is released from the crankshaft taper

. The converter will have to be held as before to prevent it turning.

. The converter will have to be held as before to prevent it turning.21. Remove the puller tool and refit the three bolts.

22. Lift off the converter. Note that the converter will still contain a quantity of oil and some may be spilled during removal.

Installation

Installation is a simple reversal of the removal procedure, with special attention to the following points:

a) Remove each pair of bolts in turn from the centre of the converter and fit new locking plates. Do NOT remove all six bolts at the same time. Tighten the bolts to their specified torque of 20 lb ft (2.9 kg m) secure with the locking plate tabs.

b) Ensure that the crankshaft taper and converter hub bore are perfectly clean and free from grease. They must be assembled dry. This is most important.

c) Refit the converter onto the output gear and align the offset slot in the converter with that in the end of the crankshaft. Refit the keyed washer.

d) Fit a new lock washer under the converter centre-bolt and tighten the bolt to 112 lb ft (15.5 kg m) while holding the converter to prevent it turning. Secure the bolt with the lock washer tab.

e) Use a new gasket when refitting the oil filter assembly to its mounting flange. Ensure that the gasket is correctly located in relation to the inlet and outlet ports on the flange and filter head.

f) When assembly is complete, check the engine oil level and top up if required.