1. Disconnect the battery earth lead as a safety precaution.

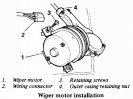

2. Disconnect the wiring connector from the wiper motor. This is a simple push-fit. Also release the earth wire from the valance, where applicable.

3. Remove the wiper arms from the drive spindles.

4. Unscrew the sleeve nut securing the rack outer tubing to the motor gearbox.

5. Remove the screws securing the motor retaining strap and release the strap from the mounting bracket.

6. Withdraw the motor assembly, pulling the cable rack from its outer tubing.

7. If required, the wiper wheelboxes can now be removed as follows:

8. Remove the sound insulation material from the bulkhead.

9. Unscrew the retaining nut at each wiper spindle and remove the spacer

.

.10. Slacken the nuts clamping the wheelboxes to the rack outer tubing and release the Bendy tubing from the wheelboxes.

The wheelboxes can then be removed.

a) Leave the tubing clamp nuts at the wheelboxes slack until after the cable rack has been inserted and the motor secured.

b) Ensure the cable rack is adequately lubricated before installing it in the outer tubing.

c) Ensure that the cable rack engages correctly with the wheelbox gear teeth.

d) After tightening the wheelbox clamp nuts, check the action of the wheelboxes before refitting the wiper arms.

e) When refitting the wiper anus, switch on the motor and stop it at the end of its stroke. Position the arms to give maximum wipe area and park position at the end of the stroke.

1. Note the alignment marks on the motor yoke and gearbox casing for reassembly.

1. Note the alignment marks on the motor yoke and gearbox casing for reassembly.2. Unscrew the two through-bolts and withdraw the yoke and armature from the gearbox. Keep the yoke and armature clear of metallic particles which will be attracted to the pole pieces by their magnetic effect.

3. Note the respective positions of the wiring connectors at the limit switch and disconnect the brush wiring.

4. Remove the screws securing the brush gear assembly to the gearbox casing and detach the brush gear.

5. If required, the brushes can be withdrawn from their insulating plate.

6. If the main brushes (diametrically opposite) are worn down to 0.20 in (5 mm), or if the narrow section of the third brush is worn to the full width of the brush, the brushes must be renewed. If the brush springs are not satisfactory, the complete brush gear assembly should be replaced.

7. Assemble the brushes to the insulating plate and refit the plate on the gearbox casing.

8. Refit the yoke and armature, ensuring that the alignment marks are adjacent.

9. Reconnect the brush leads to the limit switch, ensuring that they are refitted in their original positions.

10. Test the motor before refitting it on the car.